Select any panel type to learn more.

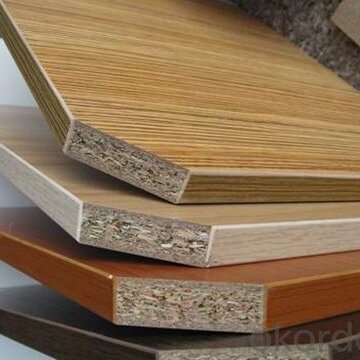

Melamine, Cold Roll

Cold roll melamine is a more affordable alternative to thermally fused melamine for projects in vertical or low-wear areas that don’t call for high-pressure laminate.

Unlike thermally fused melamine, cold roll melamine can have a veneer core substrate along with MDF or particleboard substrates.

Availability:

Cold roll melamine is available through special order in a variety of colors and wood grains.

Medium Density Fiberboard (MDF)

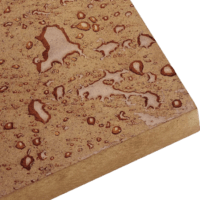

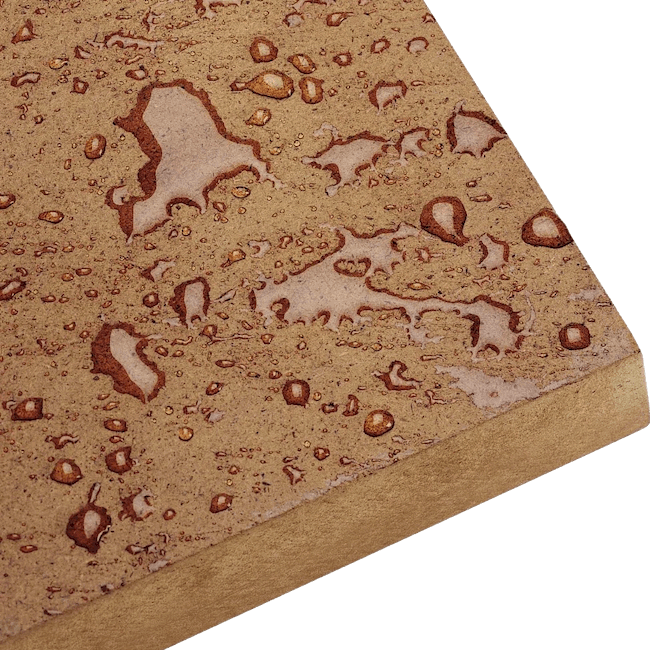

EXTIRA® Exterior MDF

EXTIRA® is a revolutionary product that performs better than wood or MDF. It is twice as strong as MDF, and is made to be used outside.

EXTIRA® panels are sanded two sides for a smooth, unprimed surface that is moisture, rot, and termite resistant.

EXTIRA® is easy to work with; can be carved, routed and machined, and can be used for virtually any non-structural paint grade application including exterior millwork, door and window parts, signage, garage doors and other architectural components.

EXTIRA® panels are covered by an industry-leading 10-year limited warranty that far exceeds competitive panel products.

Availability:

Panel Sizes

- 1/2″ thick: 49”× 97”, 25” x 194”

- 3/4″ thick: 49”× 97”, 49” x 194”

- 1″ thick: 49”× 97”

- 1 1/4″ thick: 49”× 97”1-1/4″ – 49×97

Visit: jeld-wen.com/en-us/extira

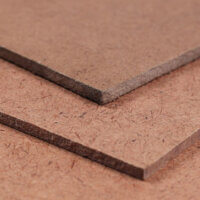

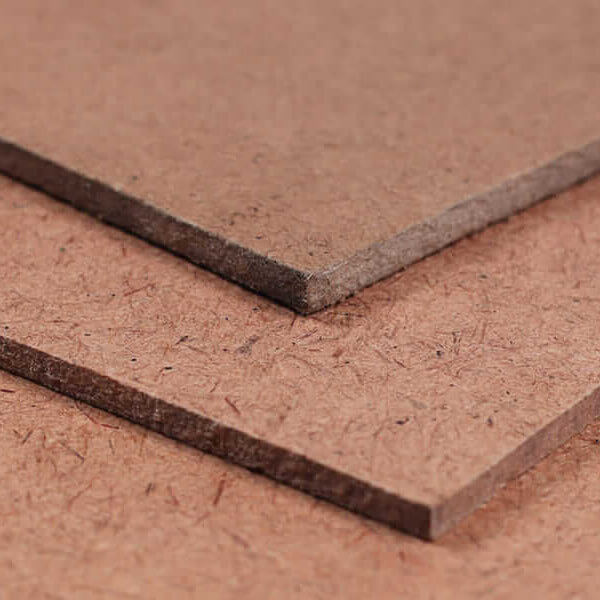

Standard Weight MDF Panels

Medium Density Fiberboard panels are made by taking fine hardwood or softwood fibers and compressing them together with an adhesive under a heated press.

MDF produces the flattest, most consistent panel with workable edges. MDF carries an average density of 49 lbs per cubic foot.

Availability:

Panel Sizes

- 1/8″ thick: 49”× 97”

- 1/4″ thick: 49”× 97” , 61” x 97”

- 1/4″ thick: 49”× 97” Beaded 1.5″ OC

- 1/4″ thick: 49”× 97” G1S Painted White

- 3/8″ thick: 49”× 97”, 61” x 97”

- 1/2″ thick: 49”× 97”, 49” x 121”, 61” x 97”, 61” x 121”

- 5/8″ thick: 49”× 97”, 49” x 121”, 61” x 97”, 61” x 121”

- 1-1/16″ thick: 49”× 97”, 49” x 121”, 61” x 97”, 61” x 145”

- 3/4″ thick: 49”× 97”, 49” x 121”, 49” x 145”, 61” x 97”, 61” x 121”, 61” x 145”

- 15/16″ thick: 49”× 97”, 61” x 97”

- 1″ thick: 49”× 97”, 61” x 97”, 61” x 121”

- 1-1/8″ thick: 49”× 97”, 61” x 97”

- 1-1/4″ thick: 49”× 97”, 61” x 97”

CARB Phase I&II, No-added Urea Formaldehyde (NAUF), Moisture Resistant (MR), Fire Rated (FR), and Forest Stewardship Council (FSC) Certified specifications can be met upon request.

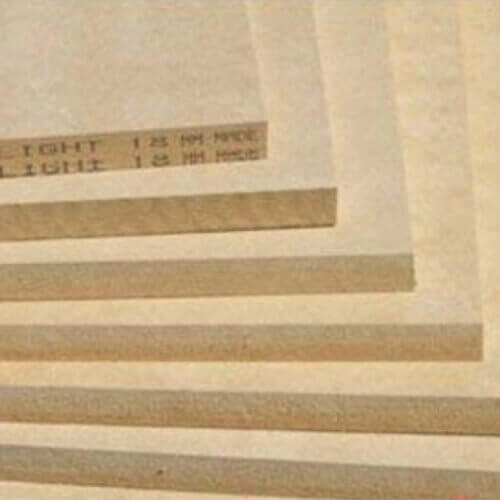

Light & Ultra Light MDF

Lightweight MDF is specifically engineered for weight sensitive applications as it has an average density of only 34 lbs per cubic foot (compared to 49 lbs per cubic foot for regular MDF).

The product provides a smooth, flawless surface, and a smooth density profile.

Lightweight MDF is an ideal choice for millwork and lamination applications where finished product weight is a concern.

Availability:

Panel Sizes

- 1/2″ thick: 49”× 97”, 49” x 121”

- 5/8″ thick: 49”× 97”, 49” x 121”

- 3/4″ thick: 49”× 97”, 49” x 121”

- 1″ thick: 49”× 97”

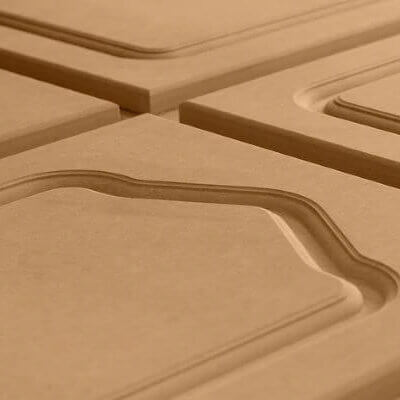

Double Refined (Door Grade) MDF

Door grade MDF is designed specifically for painted and bladder pressed doors for the cabinet door industry.

Quality standards on this product ensure better machinability with no raised fibers. This is achieved by a more uniform density throughout the board with a flatter profile.

Availability:

Panel Sizes

- 1/2″ thick: 49”× 97”, 61” x 97”

- 5/8″ thick: 49”× 97”, 61” x 97”

- 3/4″ thick: 49”× 97”, 61” x 97”

MDF Shelving

Availability:

Panel Sizes

- Raw, 3/4″ thick: 11-1/4″ x 145″, 11-1/4″ x 194″, 15-1/4″ x 194″

- White Redi-Shelf, 3/4″ thick: 11-1/4″ x 145″, 15-1/4″ x 145″

Particleboard & Hardboard

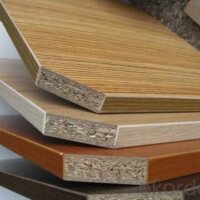

Particleboard

Particleboard is constructed with small softwood or hardwood chips mixed with an adhesive, then pressed together under a heated press to the desired thickness.

Particleboard is an excellent substrate for high pressure laminate or real wood veneers and is the least expensive of the composite wood substrates available.

The average density of particleboard is 49 lbs per cubic square foot.

Availability:

Panel Sizes

- 1/2″ thick: 49”× 97”

- 5/8″ thick: 49”× 97”

- 11/16″ thick: 49”× 97”, 49”× 121”, 61”× 97”

- 3/4″ thick: 49”× 73”, 49”× 97”, 49”× 109”, 49”× 121”, 61”× 121”

- 1″ thick: 49”× 97”

- 1-1/8″ thick: 49”× 97”, 61”× 97”, 61”× 145”

Countertop Material

- 3/4″ thick: 25” x 73”, 25” x 97”, 25” x 121”, 25” x 145”, 30” x 121”, 30” x 145”, 36” x 97”, 36” x 121”, 36” x 145”

Shelving

- 3/4″ thick:12” × 144”, 16” × 144” Square Edge

CARB Phase I&II, No-added Urea Formaldehyde (NAUF), Moisture Resistant (MR), Fire Rated (FR), and Forest Stewardship Council (FSC) Certified specifications can be met upon request.

Hardboard, Tempered

Availability:

- Tempered, Unfinished: ⅛” and ¼” thick panels

- Tempered, painted white (one-side): ⅛” thick panels

Flexible Panels

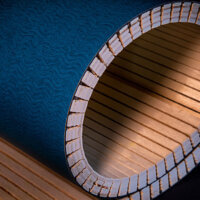

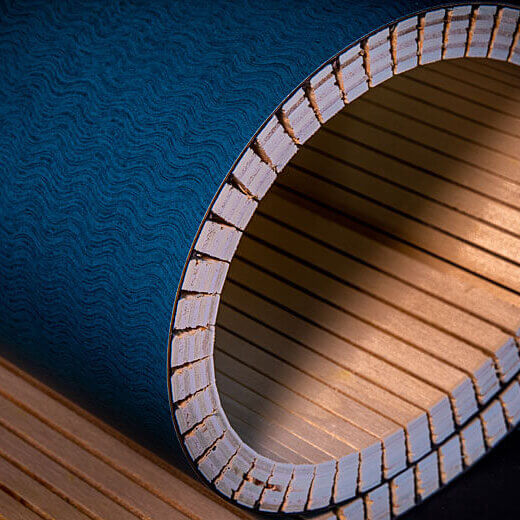

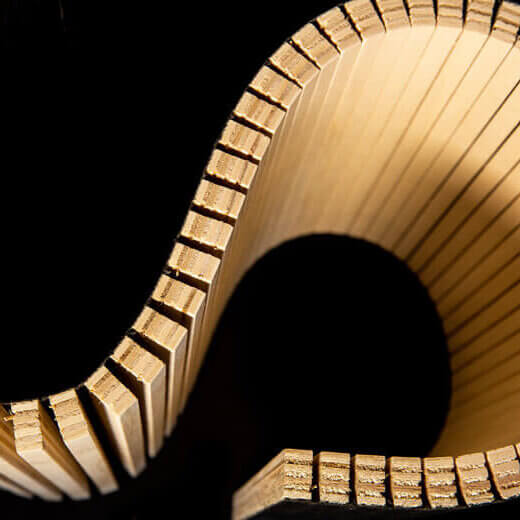

KerfKore® Flexible Panels

KerfKore® offers a full line of patented bendable substrates, lightweight structural panels and architectural panels that reduce time and money spent on contour and large feature projects.

The lightweight panels are up to 80% lighter than traditional materials and our flexible panels reduce project time by up to 70% over traditional methods, no special tools required.

KerfKore’s precision design and process ensure consistency, stability and symmetry every single time.

KerfKore® combines a unique base layer manufacturing process with an LTX Black Flexible Backer to create a highly flexible and extremely stable base layer that allows for fast and easy attachment of high-pressure laminates, veneers, metals and many other semi rigid materials.

Visit: kerfkore.com

King Plastics Products

King Plastic Corporation pioneered the first marine-grade polymer sheet, King StarBoard®, which remains the dominant brand in the marine industry today. King Plastics now produces dozens of breakthrough products for a wide variety of industries, including food service, signage, cabinetry, commercial casework and marine outfitters.

Hood Distribution and King Plastics have partnered in an effort to bring more exposure to the products that are relevant to our industry.

All of these products contribute towards LEED credits in LEED for new construction, LEED for commercial interiors, LEED for homes, LEED for schools and Green Guild for Health Care.

Visit: kingplastic.com

King StarBoard® ST

King StarBoard® ST is a high-density polyethylene (HDPE) sheet that provides a scratch-resistant surface for many applications. An advanced polymer makes the material almost 25% stronger than the original King StarBoard®.

High scratch resistance makes it especially appropriate in the construction of cabinets and furniture. Also, its high strength and stiffness make it desirable for applications where less structural support is available.

StarBoard® ST is environmentally stabilized and has been developed to withstand the harshest outdoor conditions. It can be used in wet areas that need to be washed often for cleaning, or are regularly exposed to moisture.

It can be fabricated using common woodworking tools and techniques. This product has become extremely popular in the construction of outdoor kitchens and furniture associated with outdoor living spaces.

Applications

- Concession Stands

- Dugout Areas in Sports Arenas

- Furniture

- Healthcare Case Goods

- Indoor and Outdoor Cabinets

- Kick Plates

- Lockers

- Outdoor Kitchens

- Playgrounds

- Pool Areas

- Tabletops and Counters

Availability

Readily Available Colors

- Black

- White

- Evergreen

- Seafoam

- Mocha Brown

- Sanshade

- Everglade

- Dolphin Gray

- Charcoal Gray

Standard Sheet Sizes

- 1/4″ thick: 48” x 96”

- 1/2″ thick: 48” x 96”

- 3/4″ thick: 48” x 96”

Additional thicknesses, sheet sizes, and specialty colors are available through special order.

Visit: kingplastic.com

King MicroShield®

Many of King Plastic Corporation’s products can be upgraded to King MicroShield® with advanced antimicrobial technology for protecting the product surface against stain and odor causing bacteria, algae and fungi.

Applications

- Assisted Living Facilities

- Cabinetry and Storage Carts

- Clean Rooms

- Correctional Facilities

- Day Care Centers

- Medical and Dental Facilities

- Animal Science and Veterinary Facilities

- Commercial Laboratories

- Pharmaceutical Laboratories

- Locker Rooms

- Rest Rooms

- Pool Areas

Disclaimer: King MicroShield® does not protect users or others against disease-causing bacteria. Always clean this product thoroughly after each use.

Visit: kingplastic.com

King ColorBoard®

King ColorBoard® is a high density polyethylene (HDPE) sheet that is environmentally stabilized for outdoor use.

Its bright, primary colors make it ideal for sign, industrial, marine, playground and recreational applications.

King ColorBoard® will never fade or discolor in direct sunlight and won’t delaminate, rot or warp.

Applications

- Architectural Applications

- Carnival Games

- Marine Applications

- Picnic Tables

- Point-of-Purchase Displays

- Signage and Wayfinding

Availability

ColorBoard® is available through special order in a variety of colors, thicknesses, and sheet sizes.

Visit: kingplastic.com

King Plasti-Bal® Partitions

King Plasti-Bal® is a heavy-duty, aesthetically attractive, graffiti resistant, easy to clean, HDPE board designed for commercial architectural and industrial applications.

It will never warp, rot or delaminate when exposed to water and humidity.

King Plasti-Bal® is durable, low maintenance and never needs painting or refinishing.

Applications

Benches

Lockers

Restroom Partitions

Shower Enclosures

Vanities and Countertops

Availability

Plasti-Bal® is available through special order in five standard colors and sheet sizes of 1″ x 55.5″ x 144″.

Visit: kingplastic.com

Specialty Plywood

Roseburg BoatPly

BoatPly was developed by Hood Distribution and Roseburg Forest Products for use in industrial applications for the Marine Industry.

BoatPly uses Douglas Fir or Radiata Pine one-piece faces that have no open knots or defects. The panels are fully sanded with 60 grit paper.

The core uses a High “C” grade veneer with tight gap tolerances.

The backs use a “C” grade veneer with no more than dime size defects that have been repaired with wood putty.

This panel uses more stringent tolerances than APA grade rules for superior strength in the Marine Construction industry.

Availability

- 1/4” thick: 4’ × 8’ BoatPly VC S1S & S2S

- 3/8” thick: 4’ × 8’ BoatPly VC S1S & S2S

- 1/2” thick: 4’ × 8’ BoatPly VC S1S & S2S

- 5/8” thick: 4’ × 8’ BoatPly VC S1S & S2S

- 3/4” thick: 4’ × 8’ BoatPly VC S1S & S2S & 4’ × 10’ BoatPly VC S1S

- 1” thick: 4’ × 8’ BoatPly VC S1S

Meranti Marine Grade Plywood

Aquatek Marine Grade Meranti Plywood is a multi-ply marine plywood where both the face and inner plies are constructed of whole piece, color matched, Meranti veneers.

Meranti marine plywood is 30% heavier than Okoume. It is moderately dense and has good resistance to rot and mildew.

This panel is manufactured to BS 6566. The use of slightly thicker core veneers allows this panel to be competitively priced while still being produced to a British Marine plywood standard.

This product has good machining, nailing and screw holding properties and is easily stained and glued.

Color ranges from light to dark, within the same panel.

Applications

- Boat decks and hull planking

- Cabinets and other construction

- Decking and Flooring

- Docks

- Ice houses

- Outdoor Kitchen/Furniture

- Signs

- Utility Trailer Decks

Availability

Aquatek Meranti Marine 1088 is available in sheet thicknesses of: 6mm, 9mm, 12mm, and 18mm

Okoume Marine Grade Plywood

Okoume is grown only in the equatorial west coast of Africa. It is used extensively in wooden boat building because of it’s ideal strength and durability-to-weight ratio.

We offer an Okoume-throughout plywood panel with selected cores and in compliance with BS1088 Lloyd’s Register Type Approved, marine ply recommended for nautical construction and boat furnishings.

Applications

- Manufacture of canoes, kayaks, catamarans, wooden boats and motorboats.

- Structures, creation of moulds, hull reinforcement and exterior decks of boats.

- Interior fittings for cabins of boats.

Availability

Joubert Okoume Marine 1088 is available in sheet thicknesses of: 6mm, 9mm, 12mm, 18mm, and 25mm

Visit: joubert-group.com

Fir Marine Grade Plywood

MarineTech veneer core panels are designed for rigorous marine use with superior “B” grade faces that have no open holes or defects.

Panels are fully sanded with 60 grit paper (S1S – sanded one side, S2S – sanded both sides).

These panels feature core construction that provides composed cross-bands for tight core gap tolerances that are more stringent than APA and industry specs.

One-sided panels have a high “C” grade back to provide minimal knot holes and splits.

Two-sided panels have a “B” plugged back to provide no open knot holes or defects.

Interior cores are one piece high “C” grade.

Applications

- 1/4″ thick: 4’ x 8’ MarineTech S1S & S2S

- 3/8″ thick: 4’ x 8’ MarineTech S1S & S2S

- 1/2″ thick: 4’ x 8’ MarineTech S1S & S2S

- 5/8″ thick: 4’ x 8’ MarineTech S1S & S2S

- 3/4″ thick: 4’ x 8’ MarineTech S1S & S2S

- 1″ thick: 4’ x 8’ MarineTech S1S

Larger panel sizes and tongue & groove (⅝” and thicker) panels are available through special order.

We also offer veneer core, full thickness panels constructed of slow growth inland Douglas Fir and Western Larch to yield fine-grained, smooth faces.

All back and inner plies are a “B” grade or better and will be full length. Panel edges will not have any cross-band gaps or edge splits in excess of 1/8″.

Availability

- 1/4″ thick: 4’ x 8’ A-B

- 3/8″ thick: 4’ x 8’ A-B

- 1/2″ thick: 4’ x 8’ A-B

- 3/4″ thick: 4’ x 8’ A-B

- 1″ thick: 4’ x 8’ A-B

Larger panel sizes and tongue & groove (5/8th and thicker) panels are available through special order.

Fir Plywood

Availability

- 15/32″ A-C

- 23/32″ A-C 4’ ×8’ & 61” × 121”

- 31/32″ B-C

- 23/32″ A-C 4’×8’ & 4’×10’ Fire Treated

Fir, Medium Density Overlaid (MDO) Plywood

Medium Density Overlay (MDO) is a preferred product for sign making applications.

Availability

- 3/8″ MDO 1-side, Raw (Unprimed)

- 1/2″ MDO 1-side & 2-side, Raw (Unprimed)

- 3/4″ MDO 1-side & 2-side, Raw (Unprimed)

Primed panels are available through special order.

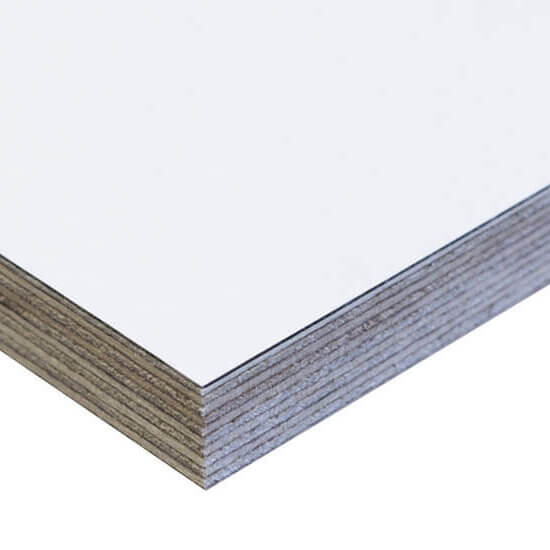

Birch Plywood with White Cabinet Liner

The panels, primarily utilizing a veneer core Chinese Birch or Sande substrate, have a thin white laminate sheet pressed to one or both sides. These panels are great for cabinet box construction (leaving a clean, white interior) or closet systems in applications where performance over a particle board core or MDF core melamine is desired.

Availability

- 5.2mm thick: Liner 1-side (Import)

- 12mm thick: Liner 1-side & 2-side (Import)

- 15mm thick: Liner 1-side & 2-side (Import)

- 18mm thick: Liner 1-side & 2-side (Import)

- 3/4″ thick: Liner 1-side & 2-side (Domestic)

Pine (Southern Yellow) Plywood, T1-11

Great for shed and out-building applications.

On-center grooves, premium grade.

Availability

5/8″ thick: 4’ x 8’ & 4’ x 12’